When it comes to reed making, the best results are achieved from a firm foundation. For reed makers, that foundation is gouged cane. Whatever your instrument, whatever your design, gouged cane is the basis upon which you build.

There are numerous gouging machines on the market today, yet all of them are variations on the same old concept – that is, by clamping cane from end to end as it sits in the bed. The fundamental error with this design is that it assumes that the cane will exactly conform to the bed’s diameter. As cane is an organic substance, no two pieces will ever be exactly alike – by any standard of measurement.

The natural variations in the diameter of the cane mean that, though the blade will make an even gouge along the bed which the cane sits in, it may not make an even thickness from a piece that does not exactly conform to the bed’s diameter.

Think about it this way, the blade and the bed of the gouging machine are fixed. When the blade moves along the bed, it does so at a specific distance above it. Now put a piece of cane which sits well in the bed at one end, and doesn’t quite at the other. After gouging that piece, you’ll have one side close to the thickness you would like, and the other not.

Of course, every piece of cane is different. In fact, it is quite common to work with material which does not conform to the diameter of the bed at all, or only in certain areas. This leads to an enormous amount of variety in thickness from piece to piece. Take look at the video below where bassoonist and reed maker Tom Hardy measures a few pieces of cane he gouges on camera. Between the four pieces there’s a variation of 0.14mm(!). Mr. Hardy intimates that the variety in results from his gouger are a reality which his process has to adapt to. Imagine if we could narrow that gap from 0.14mm to 0.02mm. That could change everything!

Sometimes when you see gouged cane advertised they give you an idea of how precise they get. If they don’t advertise it, don’t buy it! If they do, it is usually around +/-0.03mm. While we are talking about such a small measurement, a variation of 0.06mm could have a drastic effect on your reed, especially if the gouge is not even under the area which will be profiled.

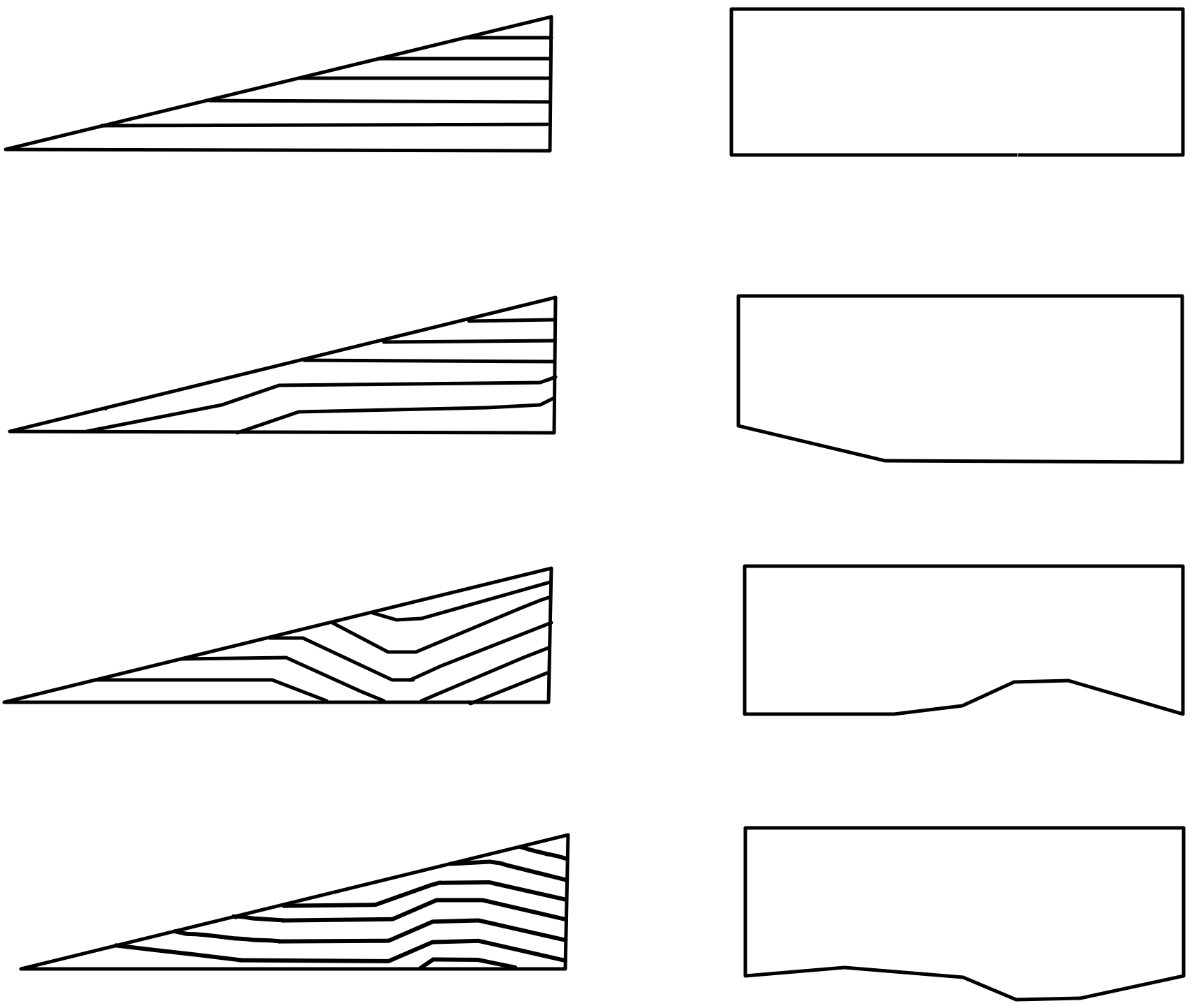

On the right is an example derived from The Bassoon Reed Manual; Lou Skinner’s Theories and Techniques by James R. McKay, et al. At the top of the left column of the image is a simplified version of Skinner’s Straight Taper profile with each horizontal line representing a layer of fibres within the piece of cane. Using a piece of gouged cane with a shape from the right column, a profiling machine set to make a straight taper might produce the corresponding results. Of course, the image shows rather extreme cases, but you can easily understand the importance of an even gouge.